GD80 graphics computer system

The system, developed at MTA SZTAKI, got its name from its "child", the GD80 graphic display, which - using the idea of the earlier GD71 - was created as the output display of a general-purpose graphic computer system to assist in engineering design work ( CAD ).

The goal of the development was to provide efficient graphical and interactive support for design, production preparation and process control tasks.

György Szántó - Miklós Janssen, Zoltán Domború, Zoltán Matkó hardware designers

Software designer: István Gallai

Use

- printed circuit board design

- parts design

- preparation of production technical drawings

- preparation of machine tool control data

- process control

- traffic control

- simulation tasks, etc.

Domestic places?

- MTA SZTAKI

- BME

- Csepel Works Machine Tool Factory

- Telefongyár

- Air Traffic Management Authority (LRI)

Foreign locations::

- Romania: Dacia factory, Pitesti

- GDR:

- TU, Dresden

- Forming technology, Erfurt

- Carl Zeiss, Jena

- Karl Marx City

SZTAKI Museum

Structure

Central-unit system

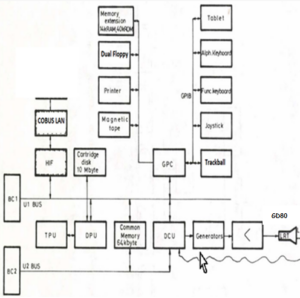

The GD80 graphics system was essentially a system of independent, microprogrammed control processors made using bit slice technology, each of which had its own internal memory (see image above):

The backbone of the system was formed by two bus systems – U1 universal and U2 special purpose – both of which were 18 address bits and 16 data bits wide.

- Display Processing Unit (DPU) and

- Display Control Processor (DCU), both had the same structure:

- word length 16 bits

- control memory: 512×48 bit PROM; expandable up to 4096×48 bit (PROM and/or RAM); cycle time 200 ns

- storage expansion hard drive (IZOT1370 / CM 5400) connected directly to the DPU, :

- 10 MB storage capacity

- Sector 12 / 24

- DMA control for the U1 bus

- storage expansion hard drive (IZOT1370 / CM 5400) connected directly to the DPU, :

- Graphics Transformation Processor (TPU)

- word length 48 bits

- control memory: 512×48 bit PROM; expandable up to 4096×48 bit (PROM and/or RAM)

- cycle time 200 ns

- temporary cache 256×48 bit

- Graphics Peripheral Controller (GPC)

- word length 8 bits

- internal storage 16 KB ROM + 16 KB RAM

- DMA data transfer

- real-time clock

- IT and GPIB bus control

- direct connection to the U1 rail

- Interface for connecting to an external (host) computer (HIF)

- bus width 8 bits

- internal storage 16 KB ROM + 16 KB RAM

- DMA data transfer

- Real-time clock

- self-developed COBUS rail control

- direct connection to the U1 rail

- Central Master Repository (CM)

- dual access (on U1 and U2 rails)

- 16 KB – 256 KB RAM

- data transfer time 300 ns

- cycle time 400 ns

Periphery

- Expansion card (cartridge)

- 16 KB RAM+ 40 KB ROM

- Double floppy disk (EC 5007)

- 2× 256 KB storage capacity

- IBM 3740-compatible sector structure

- DMA control for GPC

- Dot matrix printer (DZN180)

- 7×9 dot characters

- Magnetic tape (EC 5017)

- 9 adatsav

- DMA control for GPC on the IT bus

- Tablet (A3)

- 2×12 bit coordinates

- Alphanumeric keyboard

- 128 ASCII characters, 4 cursor controls and 16 function keys, 4 switches

- 16-character LED display

- 32-key function keyboard

- Scroll ball

- 2×12 bit coordinates

- Joystick

- 2×12 bit coordinates

- Light pen

- Control potentiometers

- 16×8 bit data

- Drawing machine (A3)

- built-in interpolator for vector drawings

Operation

The central processing unit (DPU) usually ran the KFKI TPA-70/25 instruction set and had a dual function: on the one hand, it functioned as a conventional computer, and on the other hand, it calculated the coordinates of the image to be displayed; the necessary transformation operations were performed by the high-speed transformation processor (TPU) directly connected to it. The image coordinates were stored in the main memory (CM), but if necessary, they were also available on the storage expansion hard disk directly connected to the DPU.

The image was displayed on my screen by the display control processor (DCU), with the help of generator programs, through the amplifiers. To do this, it obtained the image coordinates from the main memory (CM), via the U2 bus; but this processor also received the interactive interventions, partly from the light pen connected directly to it, partly from the graphics peripheral controller (GPC) processor, which read the data from the graphic peripheral devices (tablet, keyboards, joystick, scroll ball) via the GPIB bus.

The GPC also handled traditional storage devices (storage expansion card, floppy disk, printer, magnetic tape); it handled data traffic via the U1 bus, under the control of the processors (DPU, DCU) connected to it.

The DPU maintained communication with any external (host) computer via the COBUS bus system connected to the HIF interface.

Program set

Operating system: DOST (TPA 70/25 operating system)

Application programs developed at KFKI for TPA 70/25

Historical curiosities

The system was protected by several patents and contained a world-class new operating solution for its time.

Production was taken over by the Híradástechnika Szövetkezet in the late 1980s; the machines made there were revived by an external company, Comproject Kft.; system design and application program development, marketing and project management continued to take place at SZTAKI.

Its modular structure allowed for the construction of different configurations optimally suited to the given task. The largest system was the DARTS Air Traffic Control Simulator delivered in 1984. The system elements, consisting of a total of 9 different GD80 configurations, operated in the COBUS local area network (in the figure, GD80-BT stands for the Basic Terminal, GD80-DP stands for the Data Processing configuration, and GD80-KC stands for the seven AlfaTerminal Concentrator configurations):

The flight algorithms of the aircraft were also programmed in microcode in the simulator. This system served the training of Hungarian controllers for ten years; for another five years, Austrian air traffic controller students also studied and practiced on this system.

The simulated exercises could be planned, prepared and executed on an interactive interface on the central GD80 machine. The training included both the control of near-area (landing and taking off) and overflight traffic. The controllers could see the radar image of the planes being flown on the large round screen, which was realistically displayed on the computer operating in the background. When moving the planes, the simulator computer could take into account, in addition to the scheduled flight data, the flight parameters and weather data of all the aircraft types involved in the exercise.

The students spoke to instructors playing the role of pilots via a radio system, and they were able to intervene in the movements of the aircraft via alphanumeric terminals.

Resources

GD80_full.pdf (English)

Oral statements by József Kovács (development team member at MTA SZTAKI)

Created: 2023.02.15. 17:45

Last modified: 2024.07.07. 02:06